NickelAlloy IN718

Selective Laser Melting

High tensile, fatigue, creep and rupture strength at temperatures unto 700 °C

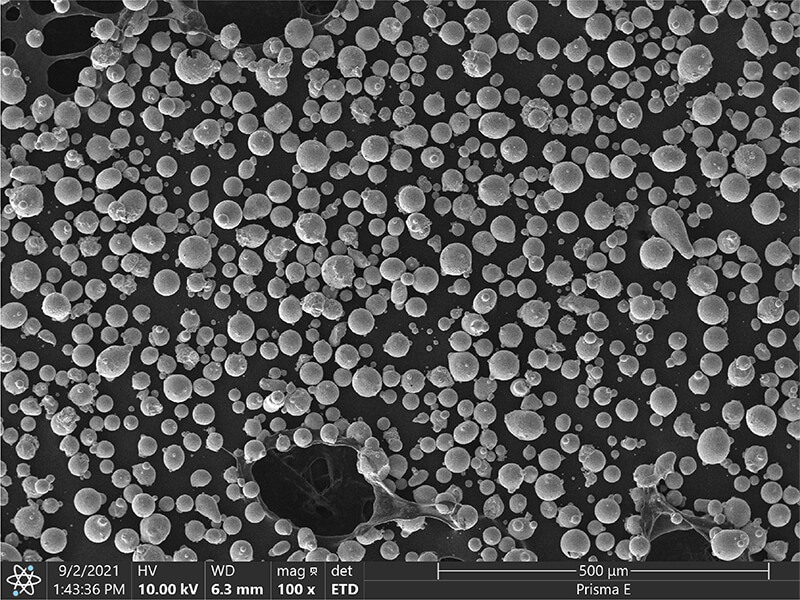

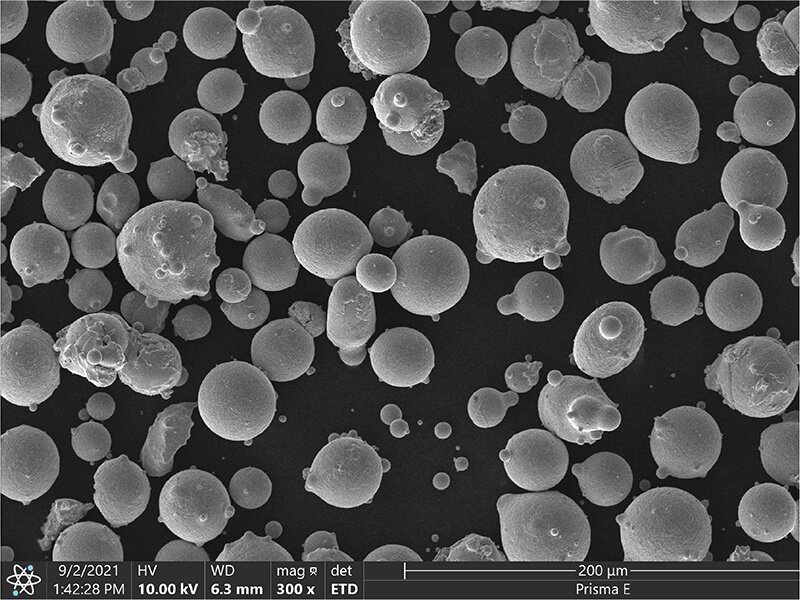

Description

NickelAlloy IN718 is a precipitation-hardening nickel-chromium alloy that is characterized by having good tensile, fatigue, creep and rupture strength at temperatures up to 700 °C (1.290 °F). Parts built from NickelAlloy IN718 can be easily post-hardened by precipitation- hardening heat treatments. In both as-built and age-hardened states the parts can be machined, spark eroded, welded, micro shot-peened, polished and coated if required. The material is ideal for many high temperature applications such as gas turbine parts, instrumentation parts, power and process industry parts etc. It also has excellent potential for cryogenic applications. Due to the layerwise building method, the parts have certain anisotropy.

Properties

The chemical composition in compliance with UNS N07718, AMS 5662, AMS 5664, 2.4668, NiCr19Fe19NbMo3

Ultimate Tensile Strength 1020 MPa

Yield Strength 710 MPa

Elongation @ Break 29%

Typical Applications

Power industry parts

Process industry parts

Load-bearing components for high temperature applications up to 700 °C, good potential for cryogenic applications

Gas turbine components

Get in Touch

+86 18664911148