Nickelalloy In939

Suitable for

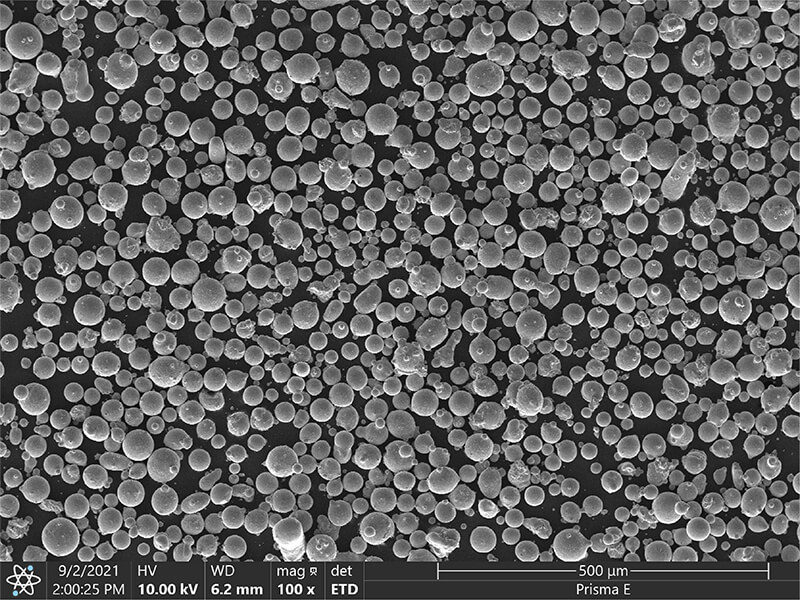

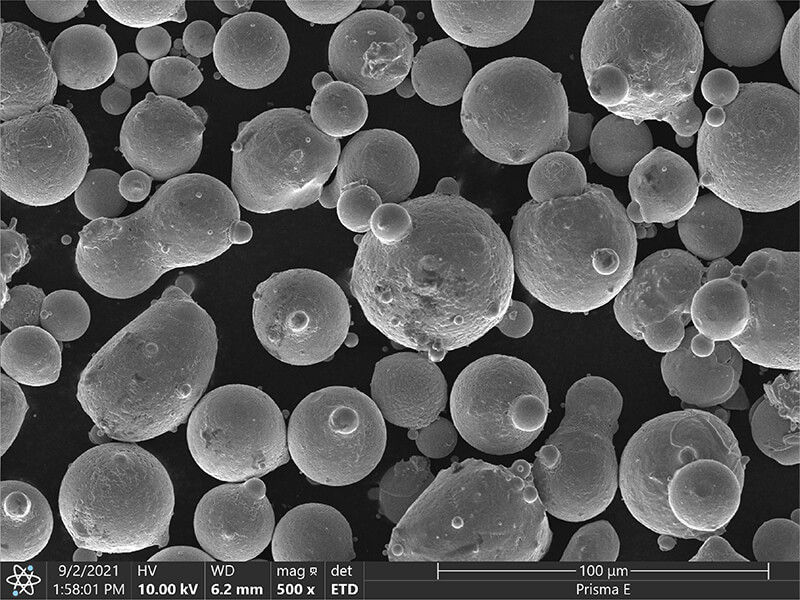

SLM(Selective Laser Melting)

High tensile, fatigue, creep and rupture strength at temperatures unto 850 °C

Maintains good ductility & resistant to strainage cracking

Excellent corrosion & oxidation resistance

Description

NickelAlloy IN939 is a nickel-chromium alloy which provides an outstanding balance of high temperature strength, corrosion and oxidation resistance, fatigue performance and creep strength at temperatures up to 850 °C (1560 °F). Parts built from NickelAlloy IN939 can be hardened after manufacture by application of precipitation hardening heat treatments.

Properties

Ultimate Tensile Strength 1510 MPa

Yield Strength 1115 MPa

Elongation @ Break 12 %

Typical Applications

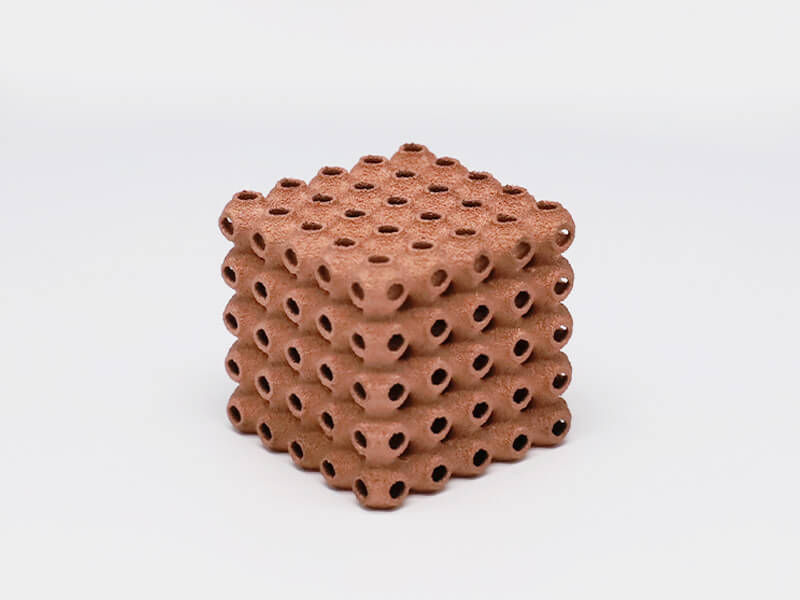

Engineering parts requiring excellent mechanical properties (fatigue, creep) and corrosion and oxidation resistance up to 850 °C

Industrial gas turbines (vanes, blades, heatshields)

Turbochargers

Instrumentation parts

Power industry parts

Process industry parts

Industrial gas turbines (vanes, blades, heatshields)

Turbochargers

Instrumentation parts

Power industry parts

Process industry parts

You may also like…

Get in Touch

+86 18664911148

+86 18664911148 (Wechat, Whatsapp)